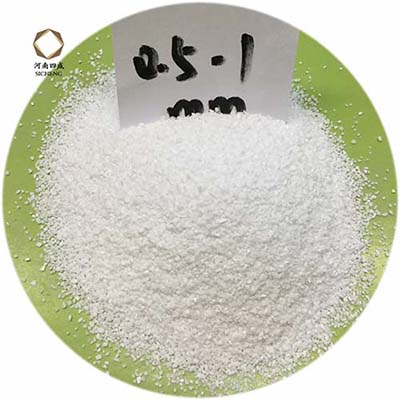

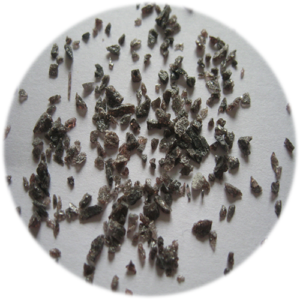

Tabular alumina in arc furnace with high grade processed alumina as raw materials. It has higher hardness and slight lower toughness comparing with brown fused alumina. It is also characterized by its high purity, ability of self-sharpening, better cutting, less heat emit, higher efficiency, acid and alkali resistance, good thermal stability. As the abrasive materials, it is suitable for grinding high-speed, high carbon steel, as loose grains, it widely used for bonded and coated abrasives, polishing, precision casting and so on.

1. Low porosity, low heat shrinkage and good heat load strength.

2. High refractoriness, high mechanical strength and abrasion resistanc

3. Good chemical purity, excellent dielectric properties and good resistance against acid and alkali corrosion.

4. The closed pores are evenly distributed inside the grain and between the grains, with high bulk density and low apparent porosity and water absorption.

IYes | chemical composition | Physical | |||||

arrive2or3 | at2or | silicon dioxide2 | he2from3 | bachelor | Apparent porosity | Water absorption | |

≥% | ≤% | ≤% | ≤% | ≥ g/cm3 | % | % | |

0-1, 1-3, 3-5, | 99.2 | 0.40 | 0.1 | 0.05 | 3.5 | 5.0 | 1.5 |

200#,320#,325 # | 99.1 | 0.40 | 0.15 | 0.05 | 3.45 | 6.0 | 2.0 |

1). Refractory materials, charge, aggregates, castable materials, tamping miscellaneous materials, plastics, pressing materials, projection materials, spray paint, vibration materials, refractory mud

2) Wear-resistant coating, refractory coating, wear-resistant machinery,

3) Smelting, casting, steel mills, power plants

4) Ceramic deburring, surface treatment

5) Refractory bricks, refractory ceramics